Olive Oil:

What You Should Know

When it comes to the world of essential oils, carrier oils are the unsung heroes, quietly but powerfully enhancing our experience. Think of them as the reliable sidekicks, supporting the superheroes – essential oils – in their quest to heal, soothe, and uplift.

Carrier oils act as a medium to dilute potent essential oils, ensuring their safe application on the skin.

This dilution not only prevents skin irritation but also allows the essential oil to be absorbed more effectively, maximizing its therapeutic benefits.

Now, choosing the right carrier oil is not a one-size-fits-all adventure. Different carrier oils offer their own array of benefits and characteristics. Ask, what do I seek in a carrier oil? Is it hydration, nourishment, or perhaps a bit of both?

Boosts immunity

Prevents joint inflammation, stiffness, and pain

Facilitates wound healing

Exhibits antioxidant properties

Controls blood clotting on the skin

Softens hair without leaving a greasy or sticky residue

Protects skin and hair against environmental toxins

Moisturizes hair and promotes its growth

Stimulates the growth of thicker, longer, and stronger hair

Eliminates dandruff and thereby supports hair growth

Reduces the appearance of aging, such as premature wrinkles and fine lines

Promotes moisture retention in skin and hair

Maintains the softness, suppleness, and radiance of skin and hair

Is an effective emulsifier in the formulation of soaps and quick-drying oils

Soothes acne and reduces chances of future outbreaks

Makes oils feel thinner in consistency when used in an oil blend, thus being beneficial for use on acne-prone skin

Has emollient properties

Extra-virgin olive oil is the pure essence of olives, crafted through a process of cold-pressing without the need for chemical refinement. This minimal processing preserves the natural fatty acids and nutrients, ensuring it retains the highest levels of beneficial components. The "extra" in its name signifies its superior quality, surpassing other varieties with its rich aroma and abundance of health benefits.

Virgin olive oil is obtained from either the second pressing of extra-virgin olive oil or from riper olives. Like its extra-virgin counterpart, it undergoes a straightforward mechanical cold-pressed extraction process. However, the drawback of virgin olive oil is that it typically originates from lower-quality olives.

Ordinary virgin olive oil, much like its virgin counterpart, is extracted solely from olives using mechanical or mild thermal methods that preserve the oil's integrity. The process involves washing, decanting, centrifuging, and filtering. However, it's important to note that oils produced through solvent-based or re-esterification techniques, as well as those contaminated with other oil sources, do not fall into the category of ordinary virgin olive oil. With a maximum oleic acid content of 3.3%, it is considered to be of lesser quality compared to other varieties.

Refined olive oil undergoes a process that utilizes chemical treatment to filter out high acid content and unwanted odors, often employing chemicals or charcoal to neutralize them. However, at NDA, our refined olive oil undergoes solely physical refinement without chemical treatment. It may also be labelled as 'pure olive oil' or simply 'olive oil.'

Stems of olives, left after the extraction of virgin oil from the fruit pulp. The amount of oil remaining in this pomace is minimal, making it impractical to extract through pressing alone. Therefore, a combination of high heat and chemical solvents, such as hexane, is utilized to extract the oil from the pomace.

The efficiency of mechanical picking correlates inversely with the force required to detach olives, which decreases as olives ripen. Consequently, as olives mature, a higher percentage tends to be dislodged by shakers. However, olive ripeness also significantly influences the quality of virgin olive oil (VOO). Oil extracted from overripe olives tends to possess a ripe flavor and sweet taste, which may not be as favored by consumers compared to oils with a slightly bitter taste and green aroma. Therefore, harvesting time becomes a balancing act between oil quality and harvesting efficiency. This balance is often achieved through a visual inspection of the olives by the foreman. The ripeness of olives can be assessed using a table that categorizes them into seven levels based on visual characteristics. Levels 5 and 6 are typically preferred by producers for obtaining extra-virgin olive oils.

After harvesting, the olives are then transported to the olive mill, which may be located on the farm or several kilometers away. Regardless of the distance, it's crucial to transport the olives in a manner that ensures adequate air circulation to prevent temperature elevation in the lower layers of the olives. This can be achieved using containers with capacities ranging from 25kg to 300kg. Regardless of the transport method, it's imperative to store the olives under optimal conditions from harvest to processing at the mill. Ideally, this timeframe should not exceed two days to maintain the sensory profile of healthy, optimally ripe olives. This step marks the beginning of various processes at the olive mill required to produce virgin olive oil. The following diagram outlines each step along with the machinery involved.

Upon arrival at the olive mill, the olives exhibit diverse characteristics: they may be of different cultivars, varying levels of maturity, and even differing sanitary conditions, such as infestation by parasites. Consequently, it is necessary to classify batches according to predetermined quality standards. Batches are first weighed and then examined by an expert who directs them to the appropriate reception lanes based on their quality. A representative sample of olives from each batch is randomly selected for several analyses, including moisture content, free acidity, yield, and sensory evaluation.

The current harvesting process poses a risk of unintentionally collecting foreign materials along with the olives. These materials not only pose a threat to the olive mill machinery but can also alter the sensory qualities of the extracted olive oil. For instance, the presence of leaves can heighten the bitterness of virgin olive oil (VOO). Therefore, it is imperative to remove foreign materials and wash the olives immediately upon their arrival at the olive mill. This process involves the use of powerful fans to eliminate foreign vegetable matter and pipes with forced water circulation for washing the olives. By washing the olives, undesirable sensory attributes such as muddy sediment and earthiness are avoided, ensuring the quality of the resulting olive oil.

After being cleaned and washed, olives are transported via a moving belt to the processing area of the olive mill. In modern olive mills, which have gradually replaced traditional granite crushers with metal ones, semi- or fully automated systems prevail. These metal crushers, constructed from stainless steel, feature a rotating component with various shapes that operate at high speeds. Typically, a hammer-shaped piece propels the olives against either a fixed or mobile metal grating, although alternative configurations like toothed disks, cylinders, or rollers exist.

The consistency and texture of the crushed paste depend on the ripeness of the olives. Therefore, it falls upon the technician to adjust the type and speed of the crushers accordingly to prevent overheating of the olive paste, thus mitigating the risk of oxidation. For instance, crushers with small holes in the grating yield a high extraction rate, resulting in oil with elevated levels of phenols, leading to a bitter taste. Hence, the crushing process plays a pivotal role in preserving the taste, aroma, and extraction efficiency of the final product.

Metal crushers may induce emulsions that reduce overall yield; however, the mixing process, known as malaxation, counteracts this effect by promoting the coalescence of droplets generated during crushing, thereby enhancing the percentage of extractable oil. Malaxation holds significant importance in the olive oil extraction process, as effective malaxation ensures optimal oil extraction and the preservation of desirable levels of antioxidants and flavor.

Malaxation is a crucial step involving the slow stirring of olive paste, facilitating the coalescence of small droplets into larger ones and promoting the rupture of unbroken cells containing oil. Typically, malaxers consist of two or three cylindrical vats arranged in series, each equipped with a rotating helix featuring multiple wings for gently mixing the paste at low speeds (15-20 rpm). The duration of malaxation, ranging from 30 to 75 minutes, depends on the characteristics of the paste. These vats, constructed from stainless steel, feature double walls for the circulation of heated water, with temperature and time automatically regulated. The extraction yield is directly influenced by these variables; higher temperatures and longer malaxation times yield increased extraction rates. However, it's crucial to maintain the paste temperature below 30°C to prevent undesirable changes in oil color, increased acidity, and degradation of volatile compounds, which could result in a virgin olive oil (VOO) exhibiting negative sensory attributes associated with heating.

Growing demand for VOOs with elevated phenol content has driven advancements in malaxer technology. These modern malaxers now operate within a nitrogen-controlled atmosphere, maintaining around 2% oxygen content. This environment facilitates the production of VOOs with superior sensory and nutritional qualities, particularly when the temperature remains within the range of 25-27°C, and the entire process concludes within 60 minutes.

Olive paste comprises liquids like olive oil and olive mill wastewater (OMW), alongside solids such as kernel fragments and tissues. The subsequent step involves separating olive oil from these constituents, achievable through pressure, percolation, or centrifugation methods.

Modern olive oil mills favor centrifugation systems for VOO extraction, owing to their ability to yield high-quality oils at lower production costs. Centrifugation, a continuous process, utilizes Stoke’s law to segregate olive oil from water and solids within a decanter centrifuge. The decanter, featuring a co-rotating scroll with helical blades, rotates at 3500-3600 rpm, driving the olive pomace to one end and directing oil and water to the other.

The paste is transferred from malaxing vats to the centrifuge via a mono pump, where lukewarm water is added to enhance fluidity. However, this increases OMW output, prompting the adoption of more eco-friendly methods like the two-phase decanter system. These decanters, consuming minimal water, predominantly feature in modern olive mills, with approximately 95% of Spanish mills utilizing this system. While they offer comparable quality to three-phase decanters, their notable difference lies in increased bitterness perception due to higher phenol levels, attributed to the absence of water during centrifugation.

Regardless of the extraction method employed (pressure, percolation, or centrifugation), a final centrifugation of the virgin olive oil (VOO) is necessary to eliminate water and small solids from the oil. This process occurs in vertical centrifuges spinning at high speeds (6000-7000 rpm). Warm water is introduced to cleanse the oil of fine particles. The technician has the flexibility to adjust the ring size, thus modifying the phase separation point and consequently the ratio of oil to water at the outlet.

Temperature and throughput represent additional variables requiring control. Low temperatures can result in oil losses with the vegetable water, whereas excessively high temperatures can yield oil lacking in desirable flavor. Insufficient water addition can lead to inadequately cleaned oil. The aim of this stage is to achieve purified oil containing less than 0.2% moisture and volatile matter (as a percentage of weight), as well as less than 0.1% insoluble impurities in light petroleum (as a percentage of weight).

Glass stands as the optimal container for olive oil due to its recyclability, impermeability to oxygen, ability to provide an airtight seal, inert nature preventing any transmission into the oil, and the light-blocking properties of colored glass. Typically, oil is bottled with nitrogen to prolong its shelf life. However, oils stored in clear glass exposed to room temperature light can lose their fruity/green aroma within two to three months and may become rancid shortly thereafter.

Olive oil's versatility as a carrier oil for essential oils makes it a valuable addition to your skincare and hair care routines. Whether you're looking to pamper your skin with a nourishing facial serum or revitalize your hair with a luxurious hair mask, olive oil provides a natural and effective base for essential oil blends. Experiment with these recipes and discover the transformative power of olive oil for holistic beauty care.

Its molecular structure allows it to penetrate deeply into the skin, delivering essential oils effectively. Rich in antioxidants, vitamins E and K, and fatty acids, olive oil nourishes and moisturizes the skin while enhancing the therapeutic benefits of essential oils. Additionally, olive oil boasts anti-inflammatory and antimicrobial properties, making it suitable for various skin types and conditions.

1 tablespoon of extra virgin olive oil

3 drops of lavender essential oil

3 drops of frankincense essential oil

2 drops of geranium essential oil Mix all the ingredients in a small amber glass bottle. Apply a few drops to cleansed skin before bedtime for a rejuvenating overnight treatment.

4 drops of chamomile essential oil

3 drops of lavender essential oil

3 drops of rosemary essential oil

Combine the ingredients in a bowl and gently massage onto the body after a warm bath or shower. This calming blend helps relax muscles and alleviate tension.

2 tablespoons of extra virgin olive oil

1 ripe avocado (mashed)

1 tablespoon of honey

5 drops of rosemary essential oil

Mix all the ingredients in a bowl until well combined. Apply the mixture to damp hair, focusing on the roots and ends. Leave it on for 30 minutes before rinsing thoroughly with warm water. This luxurious hair mask deeply moisturizes and revitalizes dull, dry hair.

2 tablespoons of extra virgin olive oil

5 drops of tea tree essential oil

3 drops of peppermint essential oil

2 drops of eucalyptus essential oil

Combine the ingredients in a small bowl. Using your fingertips, gently massage the blend into the scalp in circular motions. Leave it on for 15-20 minutes before shampooing as usual. This soothing treatment helps relieve itchiness, dandruff, and scalp irritation.

There are no known contraindications for olive oil when used in hair and skin applications. Most concern comes from consuming olive oil, which is not included in aromatherapy.

Please note, the International Federation of Aromatherapists do not recommend that Essential Oils be taken internally, unless under the supervision of a Medical Doctor, who is also qualified in clinical Aromatherapy. In addition, Essential Oils must be properly diluted before use, in order to avoid any damages to property or adverse physical effects (including injury or bodily harm).

This article is for information purposes only. All Ezzential Oils products are for external use only unless otherwise indicated. This information is not intended to diagnose, treat, cure, or prevent any disease, and it should not be used by anyone who is pregnant or under the care of a medical practitioner. Please refer to our policies for further details, and our disclaimer below.

Carrier oils act as a medium to dilute potent essential oils, ensuring their safe application on the skin.

This dilution not only prevents skin irritation but also allows the essential oil to be absorbed more effectively, maximizing its therapeutic benefits.

Now, choosing the right carrier oil is not a one-size-fits-all adventure. Different carrier oils offer their own array of benefits and characteristics. Ask, what do I seek in a carrier oil? Is it hydration, nourishment, or perhaps a bit of both?

If you’re looking for a heavy and nourishing oil, olive oil may be the right choice for you. Known for repairing skin and hair. It repairs damage, and helps maintain a radiant appearance. Keep reading to learn about all the benefits and contraindications for olive oil, its history, production, and popular uses.

The Many Benefits Of Olive Oil

Boosts immunity

Prevents joint inflammation, stiffness, and pain

Facilitates wound healing

Exhibits antioxidant properties

Controls blood clotting on the skin

Softens hair without leaving a greasy or sticky residue

Protects skin and hair against environmental toxins

Moisturizes hair and promotes its growth

Stimulates the growth of thicker, longer, and stronger hair

Eliminates dandruff and thereby supports hair growth

Reduces the appearance of aging, such as premature wrinkles and fine lines

Promotes moisture retention in skin and hair

Maintains the softness, suppleness, and radiance of skin and hair

Is an effective emulsifier in the formulation of soaps and quick-drying oils

Soothes acne and reduces chances of future outbreaks

Makes oils feel thinner in consistency when used in an oil blend, thus being beneficial for use on acne-prone skin

Has emollient properties

Olive Oil Varieties

Extra-Virgin Olive Oil

Extra-virgin olive oil is the pure essence of olives, crafted through a process of cold-pressing without the need for chemical refinement. This minimal processing preserves the natural fatty acids and nutrients, ensuring it retains the highest levels of beneficial components. The "extra" in its name signifies its superior quality, surpassing other varieties with its rich aroma and abundance of health benefits.

Virgin Olive Oil

Virgin olive oil is obtained from either the second pressing of extra-virgin olive oil or from riper olives. Like its extra-virgin counterpart, it undergoes a straightforward mechanical cold-pressed extraction process. However, the drawback of virgin olive oil is that it typically originates from lower-quality olives.

Ordinary Virgin Olive Oil

Ordinary virgin olive oil, much like its virgin counterpart, is extracted solely from olives using mechanical or mild thermal methods that preserve the oil's integrity. The process involves washing, decanting, centrifuging, and filtering. However, it's important to note that oils produced through solvent-based or re-esterification techniques, as well as those contaminated with other oil sources, do not fall into the category of ordinary virgin olive oil. With a maximum oleic acid content of 3.3%, it is considered to be of lesser quality compared to other varieties.

Refined Olive Oil

Refined olive oil undergoes a process that utilizes chemical treatment to filter out high acid content and unwanted odors, often employing chemicals or charcoal to neutralize them. However, at NDA, our refined olive oil undergoes solely physical refinement without chemical treatment. It may also be labelled as 'pure olive oil' or simply 'olive oil.'

Olive Pomace Oil

Stems of olives, left after the extraction of virgin oil from the fruit pulp. The amount of oil remaining in this pomace is minimal, making it impractical to extract through pressing alone. Therefore, a combination of high heat and chemical solvents, such as hexane, is utilized to extract the oil from the pomace.

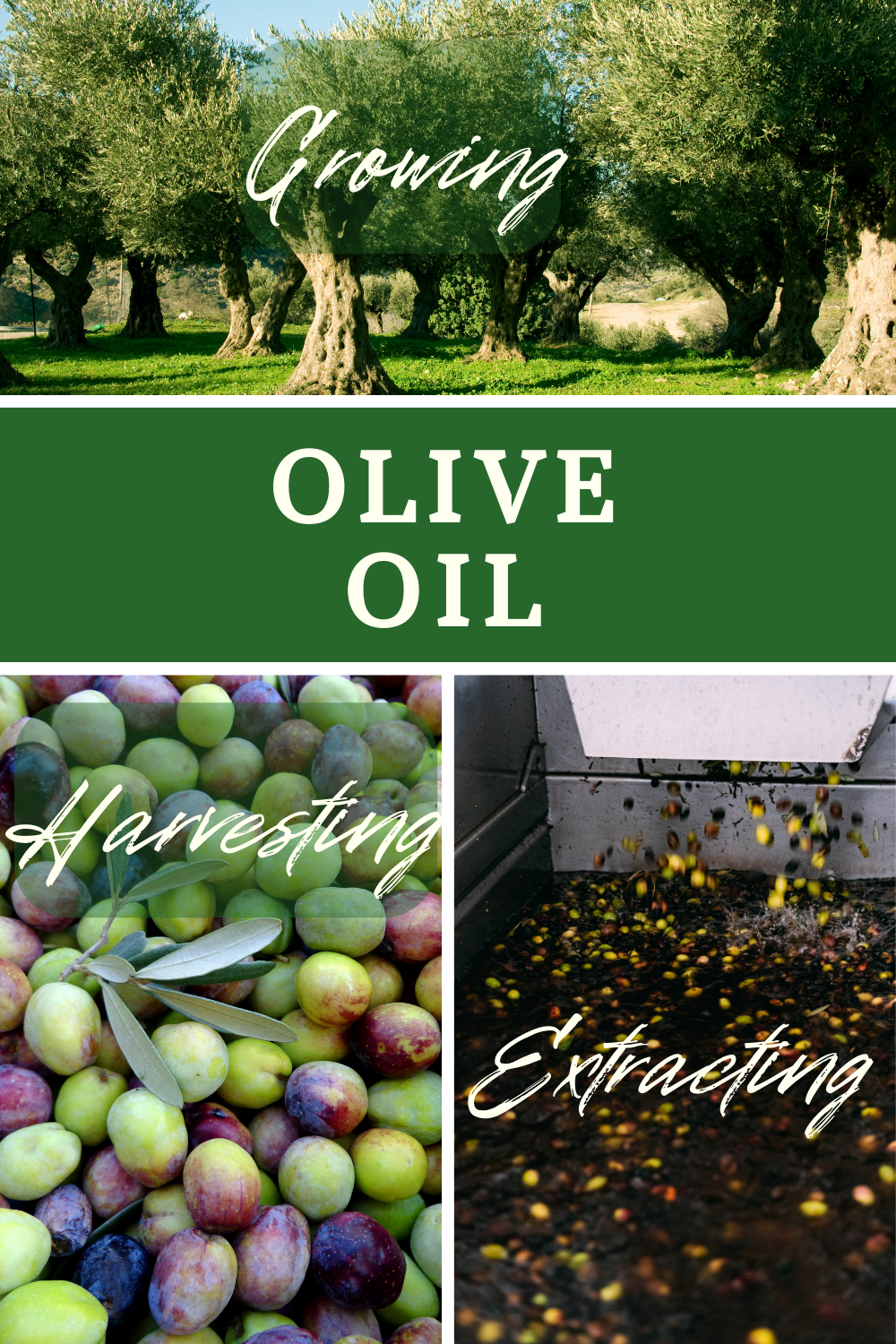

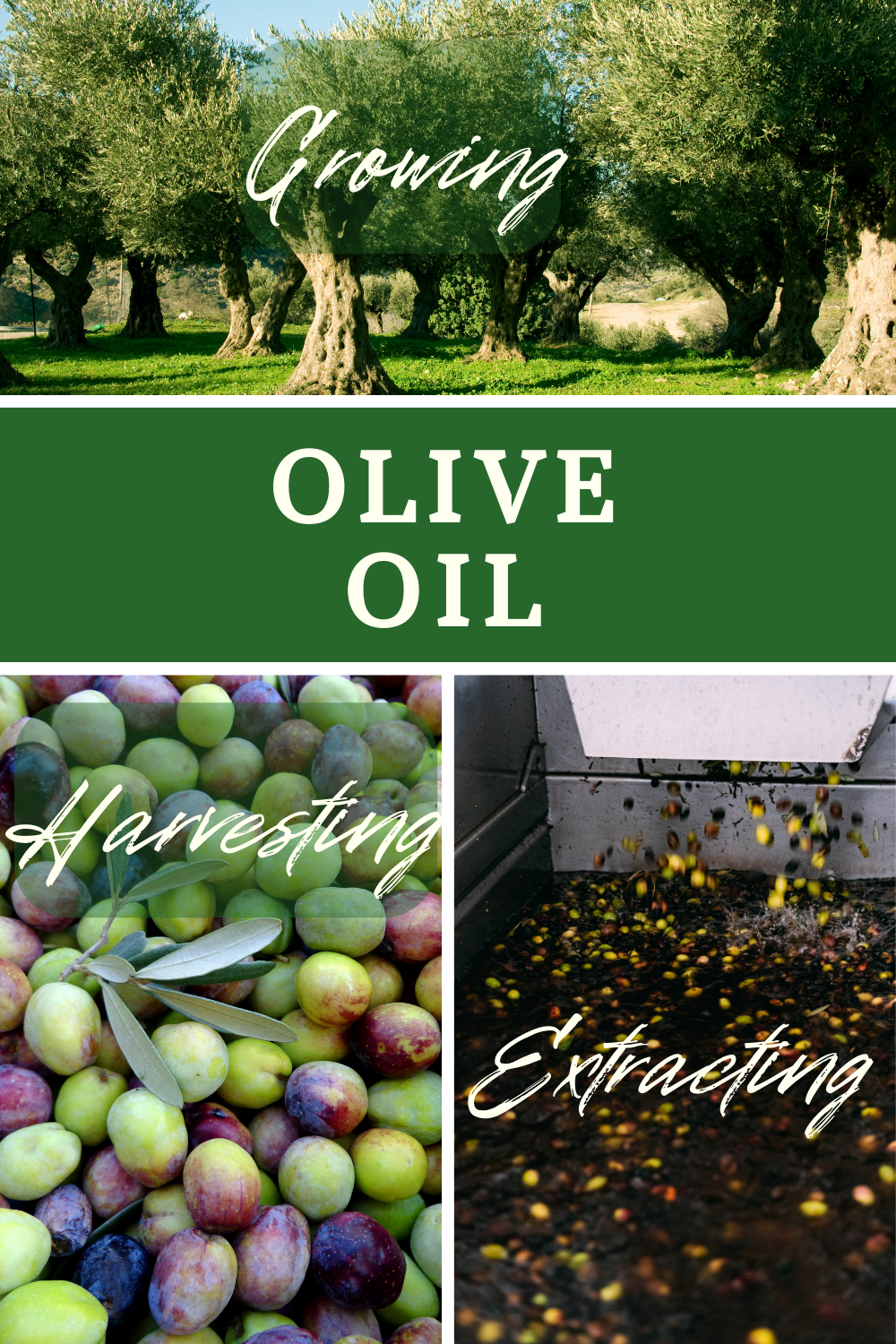

Cultivation And Extraction

Olive Harvesting

The process of olive picking significantly influences the quality of virgin olive oil (VOO), as its sensory attributes rely on the condition and ripeness of the harvested olives. Although handpicking olives was once prevalent, it is now less common in many producer countries. Instead, various types of shakers are employed to harvest olives, transmitting vibrations through the tree branches. The olives then fall onto nets placed beneath the tree canopy and are subsequently gathered using vacuum systems.

The efficiency of mechanical picking correlates inversely with the force required to detach olives, which decreases as olives ripen. Consequently, as olives mature, a higher percentage tends to be dislodged by shakers. However, olive ripeness also significantly influences the quality of virgin olive oil (VOO). Oil extracted from overripe olives tends to possess a ripe flavor and sweet taste, which may not be as favored by consumers compared to oils with a slightly bitter taste and green aroma. Therefore, harvesting time becomes a balancing act between oil quality and harvesting efficiency. This balance is often achieved through a visual inspection of the olives by the foreman. The ripeness of olives can be assessed using a table that categorizes them into seven levels based on visual characteristics. Levels 5 and 6 are typically preferred by producers for obtaining extra-virgin olive oils.

Transport of Olives to the Mill

After harvesting, the olives are then transported to the olive mill, which may be located on the farm or several kilometers away. Regardless of the distance, it's crucial to transport the olives in a manner that ensures adequate air circulation to prevent temperature elevation in the lower layers of the olives. This can be achieved using containers with capacities ranging from 25kg to 300kg. Regardless of the transport method, it's imperative to store the olives under optimal conditions from harvest to processing at the mill. Ideally, this timeframe should not exceed two days to maintain the sensory profile of healthy, optimally ripe olives. This step marks the beginning of various processes at the olive mill required to produce virgin olive oil. The following diagram outlines each step along with the machinery involved.

Upon arrival at the olive mill, the olives exhibit diverse characteristics: they may be of different cultivars, varying levels of maturity, and even differing sanitary conditions, such as infestation by parasites. Consequently, it is necessary to classify batches according to predetermined quality standards. Batches are first weighed and then examined by an expert who directs them to the appropriate reception lanes based on their quality. A representative sample of olives from each batch is randomly selected for several analyses, including moisture content, free acidity, yield, and sensory evaluation.

Olive Batch Cleaning

The current harvesting process poses a risk of unintentionally collecting foreign materials along with the olives. These materials not only pose a threat to the olive mill machinery but can also alter the sensory qualities of the extracted olive oil. For instance, the presence of leaves can heighten the bitterness of virgin olive oil (VOO). Therefore, it is imperative to remove foreign materials and wash the olives immediately upon their arrival at the olive mill. This process involves the use of powerful fans to eliminate foreign vegetable matter and pipes with forced water circulation for washing the olives. By washing the olives, undesirable sensory attributes such as muddy sediment and earthiness are avoided, ensuring the quality of the resulting olive oil.

Olive Crushing

After being cleaned and washed, olives are transported via a moving belt to the processing area of the olive mill. In modern olive mills, which have gradually replaced traditional granite crushers with metal ones, semi- or fully automated systems prevail. These metal crushers, constructed from stainless steel, feature a rotating component with various shapes that operate at high speeds. Typically, a hammer-shaped piece propels the olives against either a fixed or mobile metal grating, although alternative configurations like toothed disks, cylinders, or rollers exist.

The consistency and texture of the crushed paste depend on the ripeness of the olives. Therefore, it falls upon the technician to adjust the type and speed of the crushers accordingly to prevent overheating of the olive paste, thus mitigating the risk of oxidation. For instance, crushers with small holes in the grating yield a high extraction rate, resulting in oil with elevated levels of phenols, leading to a bitter taste. Hence, the crushing process plays a pivotal role in preserving the taste, aroma, and extraction efficiency of the final product.

Olive Paste Malaxation

Metal crushers may induce emulsions that reduce overall yield; however, the mixing process, known as malaxation, counteracts this effect by promoting the coalescence of droplets generated during crushing, thereby enhancing the percentage of extractable oil. Malaxation holds significant importance in the olive oil extraction process, as effective malaxation ensures optimal oil extraction and the preservation of desirable levels of antioxidants and flavor.

Malaxation is a crucial step involving the slow stirring of olive paste, facilitating the coalescence of small droplets into larger ones and promoting the rupture of unbroken cells containing oil. Typically, malaxers consist of two or three cylindrical vats arranged in series, each equipped with a rotating helix featuring multiple wings for gently mixing the paste at low speeds (15-20 rpm). The duration of malaxation, ranging from 30 to 75 minutes, depends on the characteristics of the paste. These vats, constructed from stainless steel, feature double walls for the circulation of heated water, with temperature and time automatically regulated. The extraction yield is directly influenced by these variables; higher temperatures and longer malaxation times yield increased extraction rates. However, it's crucial to maintain the paste temperature below 30°C to prevent undesirable changes in oil color, increased acidity, and degradation of volatile compounds, which could result in a virgin olive oil (VOO) exhibiting negative sensory attributes associated with heating.

Growing demand for VOOs with elevated phenol content has driven advancements in malaxer technology. These modern malaxers now operate within a nitrogen-controlled atmosphere, maintaining around 2% oxygen content. This environment facilitates the production of VOOs with superior sensory and nutritional qualities, particularly when the temperature remains within the range of 25-27°C, and the entire process concludes within 60 minutes.

Liquid-Solid Separation

Olive paste comprises liquids like olive oil and olive mill wastewater (OMW), alongside solids such as kernel fragments and tissues. The subsequent step involves separating olive oil from these constituents, achievable through pressure, percolation, or centrifugation methods.

Modern olive oil mills favor centrifugation systems for VOO extraction, owing to their ability to yield high-quality oils at lower production costs. Centrifugation, a continuous process, utilizes Stoke’s law to segregate olive oil from water and solids within a decanter centrifuge. The decanter, featuring a co-rotating scroll with helical blades, rotates at 3500-3600 rpm, driving the olive pomace to one end and directing oil and water to the other.

The paste is transferred from malaxing vats to the centrifuge via a mono pump, where lukewarm water is added to enhance fluidity. However, this increases OMW output, prompting the adoption of more eco-friendly methods like the two-phase decanter system. These decanters, consuming minimal water, predominantly feature in modern olive mills, with approximately 95% of Spanish mills utilizing this system. While they offer comparable quality to three-phase decanters, their notable difference lies in increased bitterness perception due to higher phenol levels, attributed to the absence of water during centrifugation.

Liquid-Liquid Separation

Regardless of the extraction method employed (pressure, percolation, or centrifugation), a final centrifugation of the virgin olive oil (VOO) is necessary to eliminate water and small solids from the oil. This process occurs in vertical centrifuges spinning at high speeds (6000-7000 rpm). Warm water is introduced to cleanse the oil of fine particles. The technician has the flexibility to adjust the ring size, thus modifying the phase separation point and consequently the ratio of oil to water at the outlet.

Temperature and throughput represent additional variables requiring control. Low temperatures can result in oil losses with the vegetable water, whereas excessively high temperatures can yield oil lacking in desirable flavor. Insufficient water addition can lead to inadequately cleaned oil. The aim of this stage is to achieve purified oil containing less than 0.2% moisture and volatile matter (as a percentage of weight), as well as less than 0.1% insoluble impurities in light petroleum (as a percentage of weight).

Olive Oil Storage

Glass stands as the optimal container for olive oil due to its recyclability, impermeability to oxygen, ability to provide an airtight seal, inert nature preventing any transmission into the oil, and the light-blocking properties of colored glass. Typically, oil is bottled with nitrogen to prolong its shelf life. However, oils stored in clear glass exposed to room temperature light can lose their fruity/green aroma within two to three months and may become rancid shortly thereafter.

Olive Oil Uses

Olive oil's versatility as a carrier oil for essential oils makes it a valuable addition to your skincare and hair care routines. Whether you're looking to pamper your skin with a nourishing facial serum or revitalize your hair with a luxurious hair mask, olive oil provides a natural and effective base for essential oil blends. Experiment with these recipes and discover the transformative power of olive oil for holistic beauty care.

Its molecular structure allows it to penetrate deeply into the skin, delivering essential oils effectively. Rich in antioxidants, vitamins E and K, and fatty acids, olive oil nourishes and moisturizes the skin while enhancing the therapeutic benefits of essential oils. Additionally, olive oil boasts anti-inflammatory and antimicrobial properties, making it suitable for various skin types and conditions.

Nourishing Facial Serum:

1 tablespoon of extra virgin olive oil

3 drops of lavender essential oil

3 drops of frankincense essential oil

2 drops of geranium essential oil Mix all the ingredients in a small amber glass bottle. Apply a few drops to cleansed skin before bedtime for a rejuvenating overnight treatment.

Soothing Body Massage Oil:

2 tablespoons of extra virgin olive oil4 drops of chamomile essential oil

3 drops of lavender essential oil

3 drops of rosemary essential oil

Combine the ingredients in a bowl and gently massage onto the body after a warm bath or shower. This calming blend helps relax muscles and alleviate tension.

Nourishing Hair Mask:

2 tablespoons of extra virgin olive oil

1 ripe avocado (mashed)

1 tablespoon of honey

5 drops of rosemary essential oil

Mix all the ingredients in a bowl until well combined. Apply the mixture to damp hair, focusing on the roots and ends. Leave it on for 30 minutes before rinsing thoroughly with warm water. This luxurious hair mask deeply moisturizes and revitalizes dull, dry hair.

Scalp Soothing Treatment:

2 tablespoons of extra virgin olive oil

5 drops of tea tree essential oil

3 drops of peppermint essential oil

2 drops of eucalyptus essential oil

Combine the ingredients in a small bowl. Using your fingertips, gently massage the blend into the scalp in circular motions. Leave it on for 15-20 minutes before shampooing as usual. This soothing treatment helps relieve itchiness, dandruff, and scalp irritation.

Contraindications For Olive Oil

There are no known contraindications for olive oil when used in hair and skin applications. Most concern comes from consuming olive oil, which is not included in aromatherapy.

Safety Information

Please note, the International Federation of Aromatherapists do not recommend that Essential Oils be taken internally, unless under the supervision of a Medical Doctor, who is also qualified in clinical Aromatherapy. In addition, Essential Oils must be properly diluted before use, in order to avoid any damages to property or adverse physical effects (including injury or bodily harm).

This article is for information purposes only. All Ezzential Oils products are for external use only unless otherwise indicated. This information is not intended to diagnose, treat, cure, or prevent any disease, and it should not be used by anyone who is pregnant or under the care of a medical practitioner. Please refer to our policies for further details, and our disclaimer below.